Heating

To achieve the optimum biogas yield, the anaerobic digestion needs constant environmental

conditions, preferably close to the process optimum. The digester temperature is of prime

importance. In temperate areas, a heating system and an insulation of the digester is

necessary. Hence, the needed temperature for digestion can be reached and a loss of

energy by transmission is compensated.

Because of the high costs for material and

installation of a heating system, a low-cost biogas

plant, as needed in developing countries, can only

be build without heating. To boost the biogas yield

for those plants, the building of a bigger digester to

increase the retention time would be cheaper. A

bigger digester reduces the required maintenance,

while a heating system, increases maintenance

requirements. A bigger digester serves also as a

buffer for sediments, pH-variations and gas storage.

For example, a fixed dome plant sized 50% bigger,

is only 10% more expensive.

The mean surrounding temperature and it’s

seasonal variations are very important. Biogas

plants without heating system work, therefore, only

in warmer regions for the whole year. In regions with

extreme temperature variations, for instance in

Turkey (hot summer, cold winter), the biogas plant

should be built under the stable. Hence the biogas

yield would be lower in summer, but constant over

the year and at the end higher. Before

implementation, at least an approximated average

temperature profile and expected extremes over the

year should be available for the site.

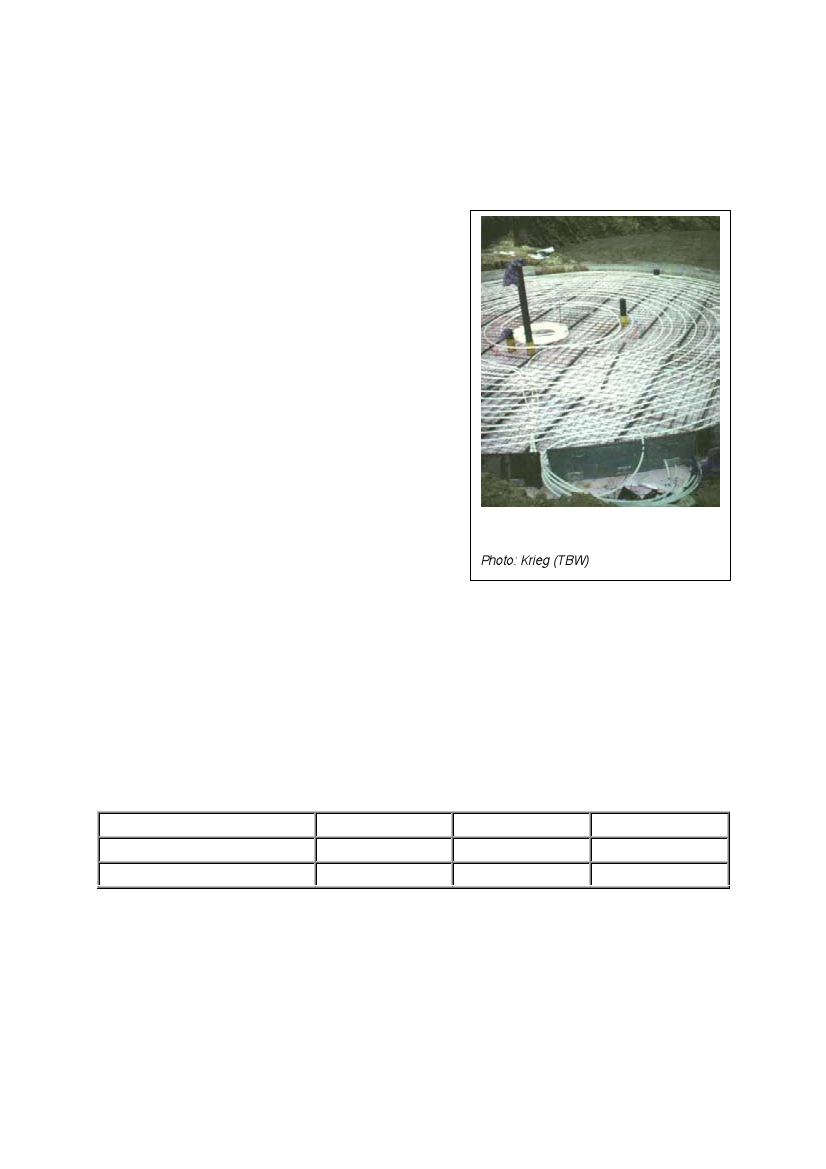

Figure 31: Heating system for a

biodigester under construction

(Germany)

Photo: Krieg (TBW)

A biogas plant with heating system and co-generation can be operated with process energy.

Nevertheless the dimensioning of such a heating system is difficult, as the substrate, which

has to be heated up, is not homogenous.

A guiding figure for a digester with a hydraulic retention time of 20 days is 270 W/m3 digester

volume. The increasing of the hydraulic retention time makes it possible to reduce the

heating power per volume. With a hydraulic retention time of 40 days the digester needs only

150 W/m3.

Following figures are for heating systems with a heating water temperature difference of 20

K:

hydr. retention time

40 days

30 days

20 days

temperature difference

heating power

20 K

150 kW/m3

20 K

210 kW/m3

20 K

270 kW/m3

A heating system located in the digester produces a thermal circulation, which is, especially

for non-agitated digesters, very important.

An indirect energy transfer by heat exchanger is most common. Exceptions are steam

injection, liquefying of solid manure with heated water and the heating by pre-aeration.

Internal and external heating systems

External heating systems have a forced flow on both sides. Due to the turbulent flow patterns

of both media, a very good heat transportation can be reached. Therefore, the surface of the

heat exchanger can be comparatively small. Nevertheless those systems cannot be

recommended for non-agitated digesters.

53